Motor

KEDE has been producing brush motor rotor and stator since 2008. After developing for dozen years, our motor products includes rotor&stator, EPS motor,Coreless motor and customized motor. We have two automatic production lines in China and two in Vietnam. We keen to provide customers with complete product cycle support from prototyping to serial production by high reliability and stable supply.

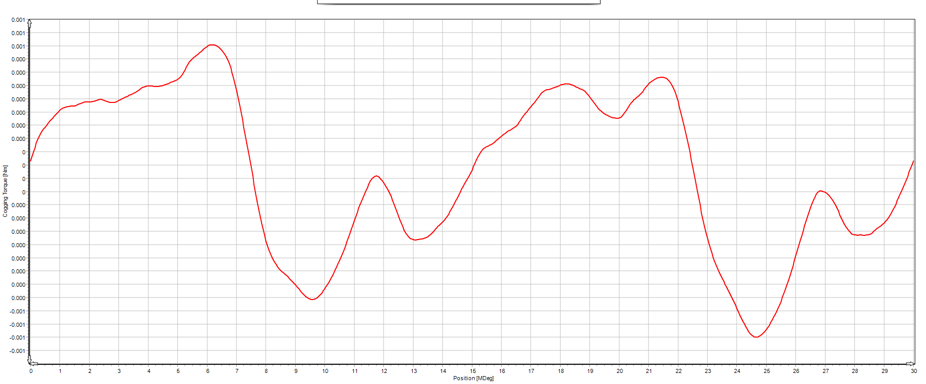

Compared with traditional steering systems, EPS motor brings many advantages like greater efficiency and driving comfort. Energy consumption is reduced by 6% in some applications. Extremely low slot torque, low noise and high power density are the main advantages of EPS motors. At present, KEDE has the manufacture capability of EPS motor and some early R&D.

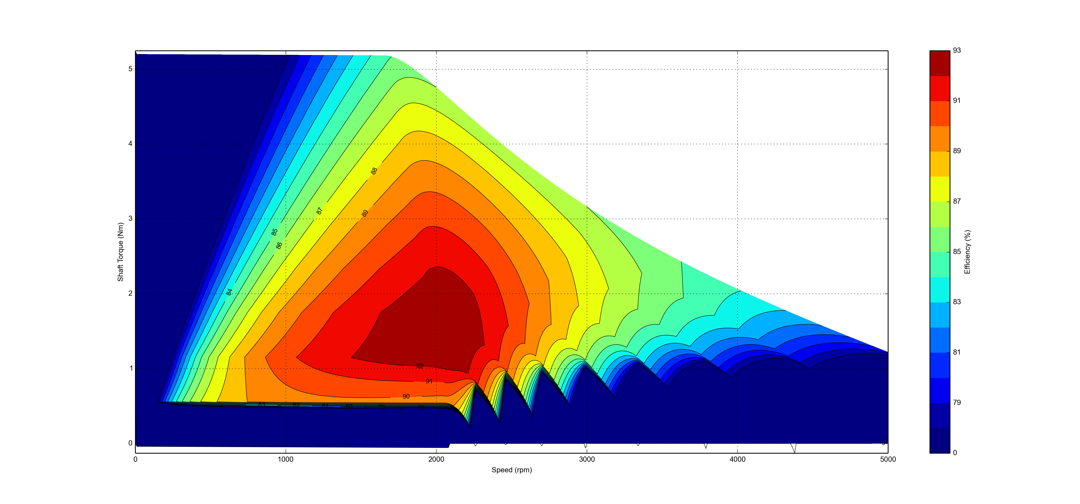

Efficiency

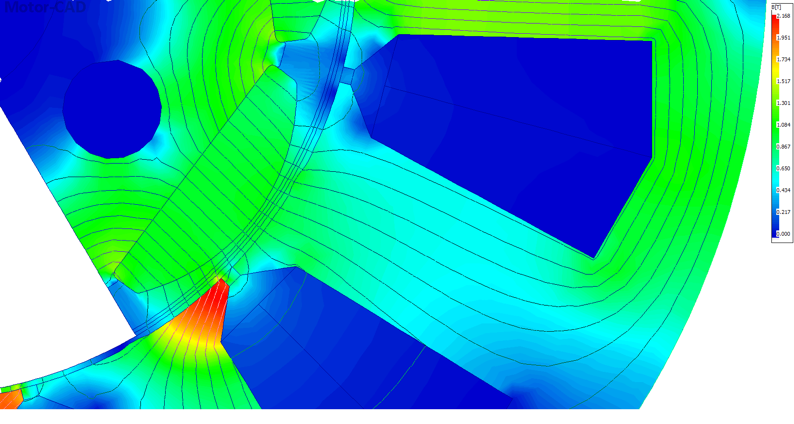

Motor load magnetic field distribution diagram

Ultra-low cogging torque of motor

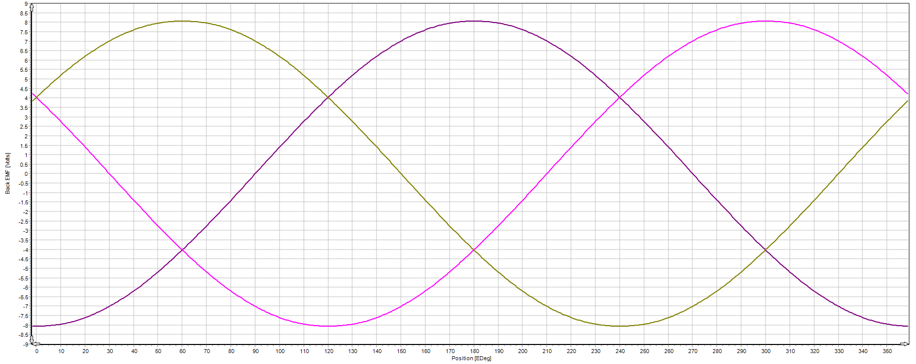

Motor back electormotive force waveform

The coreless motor is a kind of DC permanent magnet motor including brushed motor and also brushless motor. compared with the ordinary DC motor, there is no iron core which means there is no iron loss, so the efficiency is higher than the ordinary micro DC motor. The rotor is made by coil so the moment of inertia is very small and easy to control. At the same time, its weight and moment of inertia are greatly reduced, thus reducing the mechanical energy loss of the rotor itself. Due to the structural changes of the rotor, the running characteristics of the motor have been greatly improved, which not only has outstanding energy-saving characteristics, but more importantly has the control and drag characteristics that the iron core motor cannot achieve. Therefore, it is widely used in servo systems that require fast response, such as fast autofocus, highly sensitive recording and detection equipment, industrial robots, bionic prosthetics and high-end power tools.

Product introduction

Coreless motor

High torque-inertia ratio stator

with out iron core

The Coreless motor is light in weight, small in size and low in energy consumption

Special process

High efficiency and high strength rare earth magnet

Self-contained high-density packaged rotor coil

Sliding bearing or ball bearing

Metal alloy brush commutation system

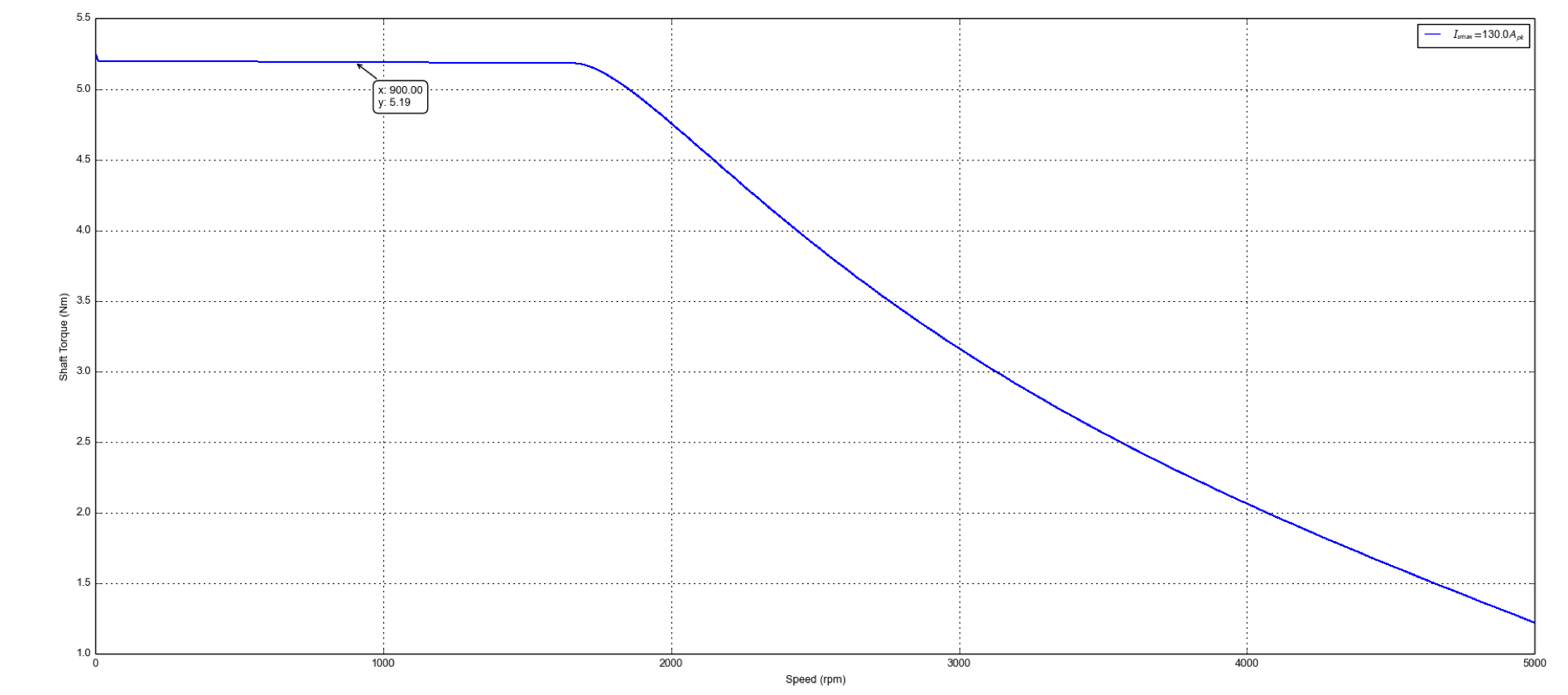

Performance parameter

Main dimension D30*68mm/D26*57mm/D25*54mm

Rated voltage: 12-48V

No-load speed: 5000-15000RPM

Locked torque: 100mN.m-1000mN.m

Application environment

Medical care

Aviation and Defense

Robots and factory automation

Power tools