Soft Magnet

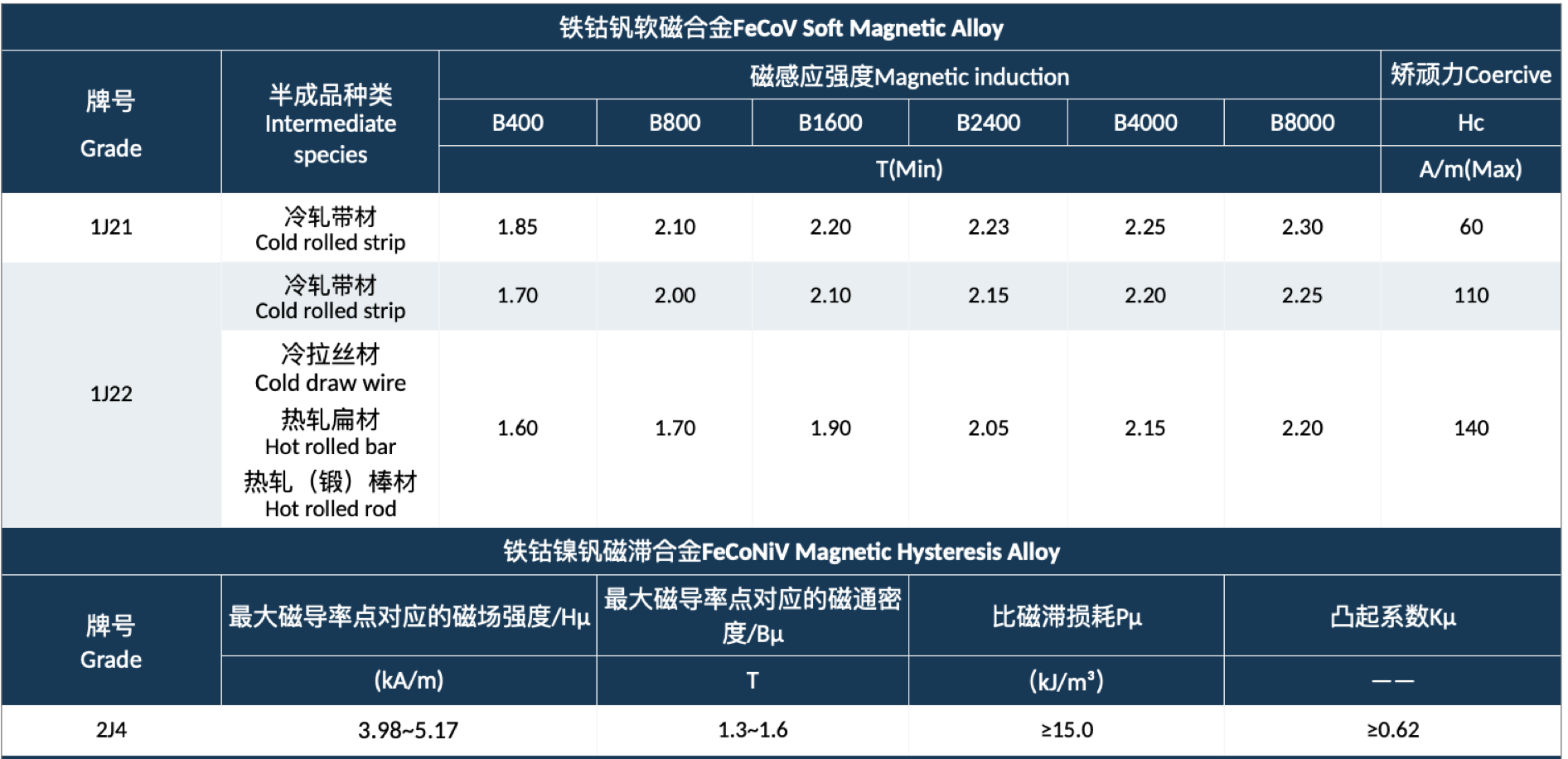

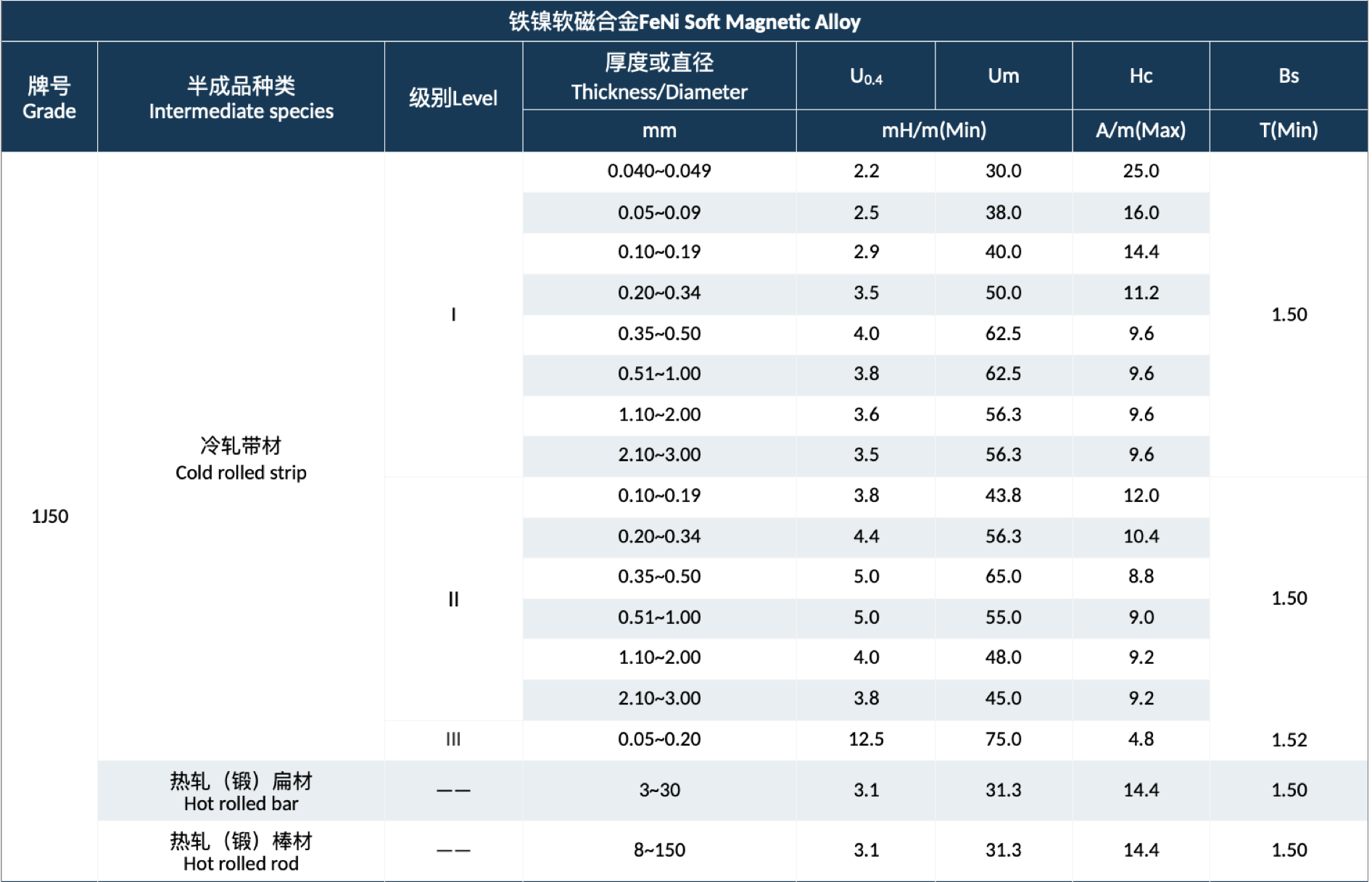

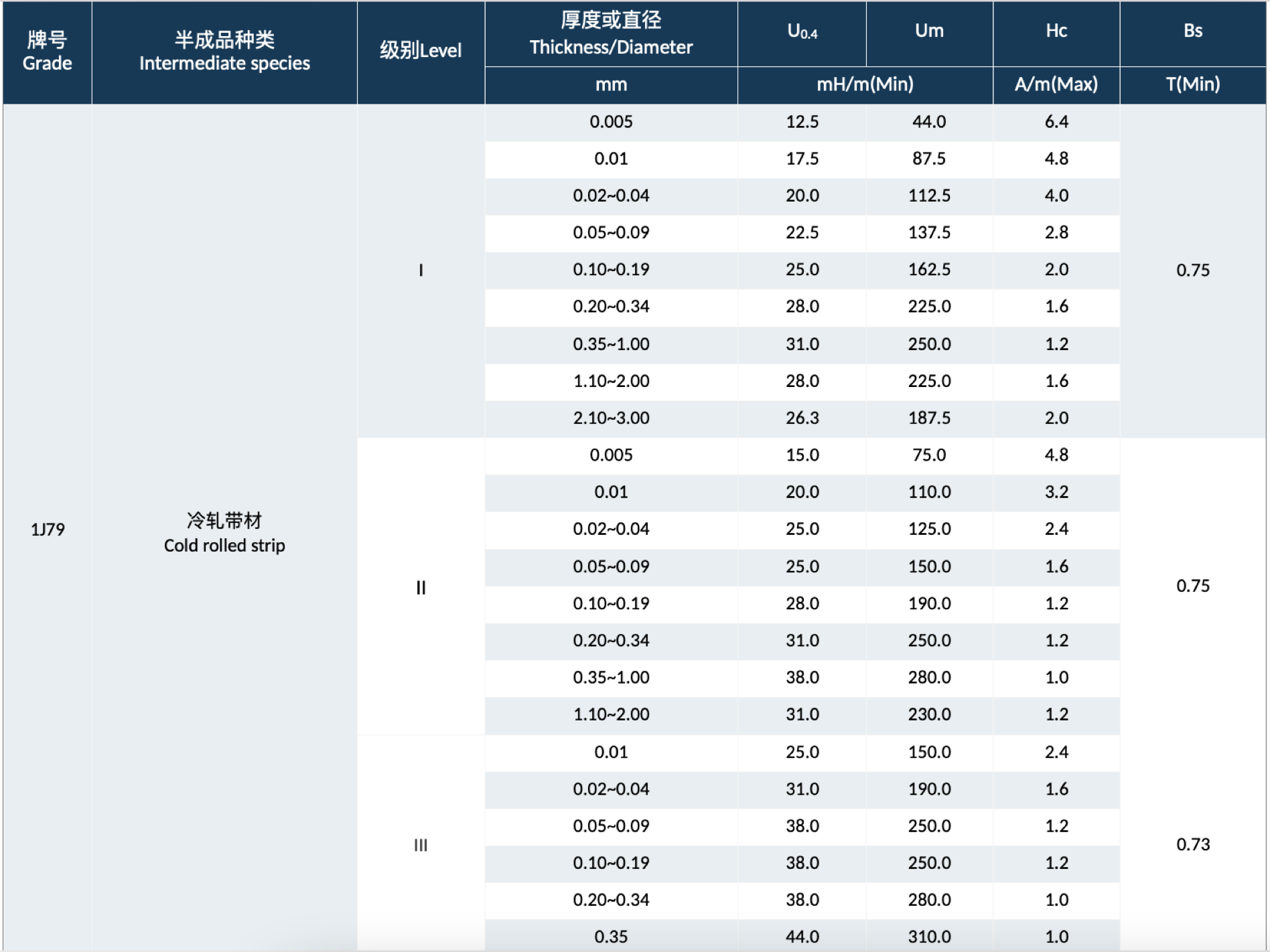

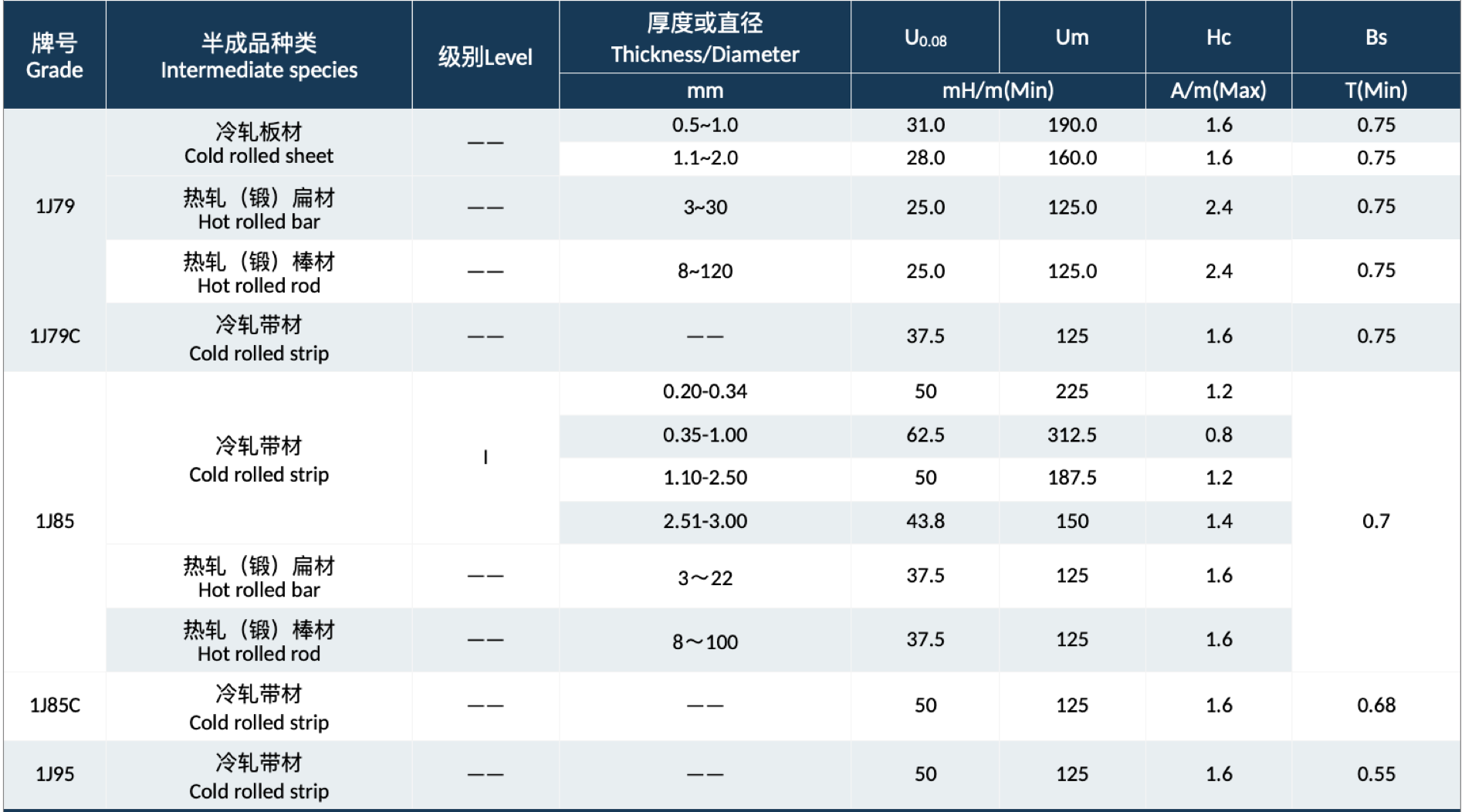

Our company has been developing and producing soft magnet since 2011, with over 10 years experience in magnetic heat treatment and mechanical machining capabilities; We maily focus on pure iron, iron silicon, iron nickel, iron cobalt, iron aluminum etc; Our company is equipped with advanced processing equipment (VFS vacuum furnace, Hass precision machining center, turning milling composite, precision surface grinder, internal and external cylindrical grinder etc.) and trustable testing equipment (CMM, NIM soft magnetic material DC performance testing instrument, B-H magnetic property testing instrument etc.). The main function of soft magnetic material is to conduct magnetism, convert and transmit electromagnetic energy. Therefore, it is widely used in electrical equipment and the radio electronics industry such as transformers, generators, motors, electromagnets, various types of relays and inductors, reactors, sensors' iron cores, magnetic shielding covers, magnetic heads, magnetic recording media, computer cores, electromagnetic suction cups, magnetic sensing components (such as magnetic thermal materials used as switches), etc.